LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

Cartridge dust collector (LTC) is a high-efficiency dust removal equipment with advanced level. It has good dust removal effect, high dust removal efficiency, reliable operation and convenient maintenance. This type of dust removal equipment adopts automatic pulse dust removal method. Widely used in air purification and material recovery in machinery, casting, ceramics, electronics, chemicals, plastics, cement, powder, food, mold, hardware and other industries.

THREE: Scope of application

It can be applied to the collection and purification of various types of powder, dust, dust and particulate matter; such as dust collection of various production equipment such as machinery industry, chemical industry, food industry, pharmaceutical industry, electronic industry, etc. Ferrous metal, mining, various furnace dust collection and various drying, stirring and mixing exhaust dust collection treatment.

Combined with the actual production conditions, or according to the actual situation and customer requirements, the equipment can be designed as explosion-proof or non-explosion-proof.

FOUR:the performance and characteristics of the filter cartridge dust collector:

1. Cartridge-type dust collector is a typical high-efficiency dust collector with stable and reliable performance and easy operation.

2. It has strong adaptability and can capture dust of various properties, and will not affect the dust removal efficiency due to properties such as specific resistance of dust.

3. It is easy to recycle dust, there is no sludge treatment, waste water pollution and other problems, and maintenance is simple.

4. Main features of filter cartridge dust removal system:

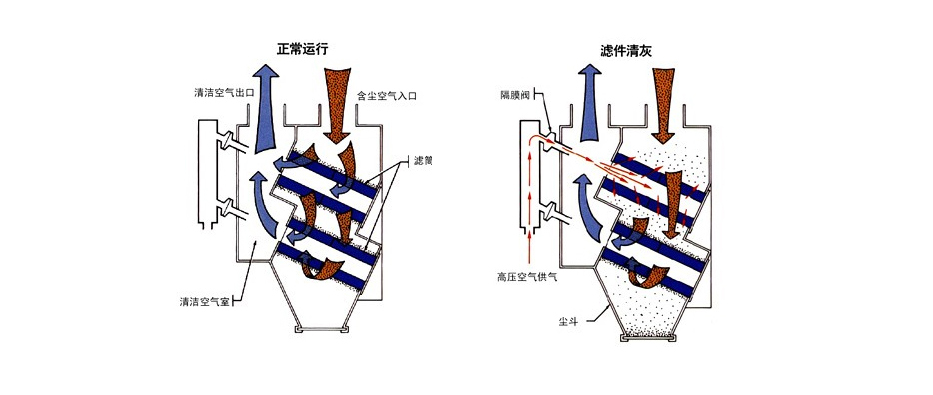

Cleaning method: The dust collecting equipment adopts automatic pulse cleaning method;

The form of pressure in the dust collector: the filter chamber of the dust collector is a negative pressure type. The dust collecting device is arranged at the inlet end of the fan, so that the dust collector operates in a negative pressure state, and the dust-containing gas is discharged through the chimney after being purified by the filter cartridge. The gas entering the fan of the negative pressure dust collection system is clean gas, which has less wear on the fan impeller and prolongs the service life of the fan.

FIVE:Structural outline drawing of filter cartridge dust collector

The structure of the filter cartridge type dust collector is composed of an air inlet pipe, an exhaust pipe, a box, an ash hopper, a ash cleaning device, a diversion device, an air flow distribution plate, a filter cartridge and an electric control device.

SIX:Performance parameters of filter cartridge dust collector

Applicable dust concentration range: 0.2~2g/m3;

Filtering wind speed: 0.40~0.70m/s;

Purify dust-containing gas with dust particle size > 0.1 μm, and the dust removal efficiency is ≥ 99.5%;

Equipment resistance: 700 ~ 1000Pa;

Blowing compressed air consumption (0.5 ~ 0.70MPa): 16 filter cartridges air consumption 0.6 ~ 1.0m3/h.

Model | Handling air volume(m³/h) | Number of filter cartridges (only) | Pulse Solenoid Valve Specifications | Cartridge Dust Collector | |||

Length(L) | Width(W) | High(H) | Inlet and outlet duct diameter(φ) | ||||

LTC-12 | 12000-15000 | 12 | DMF-T-40 | 1960 | 1362 | 2770 | 550 |

LTC-16 | 16000-20000 | 16 | DMF-T-40 | 1960 | 1960 | 2770 | 650 |

LTC-20 | 21000-25000 | 20 | DMF-T-40 | 1960 | 1960 | 2770 | 700 |

LTC-24 | 24000-30000 | 24 | DMF-T-40 | 3920 | 1362 | 2770 | 750 |

LTC-32 | 32000-40000 | 32 | DMF-T-40 | 3920 | 1960 | 2770 | 850 |

LTC-40 | 41000-48000 | 40 | DMF-T-40 | 3920 | 1960 | 2770 | 900 |

LTC-48 | 50000-57000 | 48 | DMF-T-40 | 5880 | 1960 | 2770 | 1000 |

LTC-60 | 60000-70000 | 60 | DMF-T-40 | 5880 | 1960 | 2770 | 1200 |

扬州绿之源环保科技有限公司 0514-84756600