LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

The spray scrubber (LYT) is carefully designed by our company according to the gas treatment requirements of various industries. For different gases, different packing and contact time, superficial velocity and gas-liquid ratio are used. Completely solve the problems of purification efficiency, operating cost, secondary pollution, and floor space, and successfully improve the technology of spray washing tower to a higher level.

TWO:Scope of application

1. In the field of dust removal, as a wet dust collector, it is widely used in paint mist dust removal in the painting industry, and the purified gas dust removal effect is obvious.

2. Widely used in the pollution control of lead fume or vapor in printing, battery, non-ferrous metal smelting, military and other industries.

3. Pickling waste gas or other waste gas purification in chemical industry, smelting, electroplating, picture tube, printing and dyeing, pharmaceutical, instrument, electronic instrument, machinery manufacturing and other industries.

THREE: Process flow

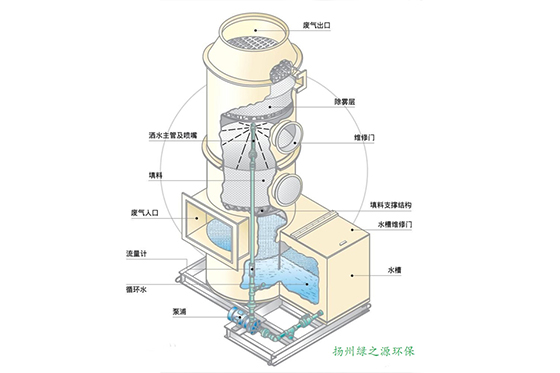

The washing liquid is atomized into fine droplets and sprayed down evenly through the nozzle. The dust-laden gas enters from the lower part of the spray tower and flows from the bottom to the top. The two are in countercurrent contact. Reunited between, so that its weight greatly increased, and settled down by the action of gravity. The collected dust is gravitationally settled in the liquid storage tank and discharged regularly. Part of the clarified liquid can be recycled, and together with a small amount of supplementary clarified liquid, it enters the spray tower from the nozzle at the top of the tower through the circulating pump for spray washing. Thereby reducing the consumption of liquid and the amount of secondary sewage treatment. The purified gas after spraying and washing is discharged from the top of the tower after removing the fine droplets entrained by the gas through the mist eliminator.

FOUR:Structural structure

The main factors affecting the dust removal efficiency of the spray tower are the uniformity of droplet distribution, droplet size and particle size distribution. Therefore, the selection of the appropriate atomizing nozzles and the rational arrangement of the nozzles is one of the keys to the design of the spray scrubber.

1. Nozzle arrangement

The arrangement of the nozzles in the spray tower should be such that the cross section of the spray tower is completely and evenly covered by the spray liquid. Generally, the arrangement of multi-layer nozzles is adopted, and the nozzles between two adjacent layers are arranged in a staggered manner. The distance between the two floors is 1-2m. A sufficient number of nozzles must be arranged on each spray layer, and the water mists sprayed by adjacent nozzles overlap and overlap each other without leaving any gaps, so that the sprayed droplets completely cover the entire section of the spray tower, and as far as possible Reduce the amount of liquid flowing along the tower wall, and at the same time reduce the direct erosion and wear of the spray liquid on the tower wall.

2. Spray coverage

The liquid sprayed from the nozzle must be able to completely cover the section of the spray tower at a certain distance from the nozzle outlet, so as to prevent the gas short-circuit problem caused by the area without spray liquid in the spray tower. Generally, the spray coverage of each spray layer is required to be 200%-300%. The spray coverage rate can be calculated as follows: Spray coverage = Nm×Am/A

In the formula: Nm—the number of nozzles in each spray layer; Am—the spray area of each nozzle measured at 1m from the nozzle outlet, m2; A—the cross-sectional area of the spray tower at 1m from the nozzle outlet, m2.

3. Spray droplet size and main design parameters

The selection of the appropriate spray droplet size is a prerequisite for determining the main design parameters of the spray tower. It is well known that under the same spraying conditions, the larger the particle size of the atomized droplets, the smaller the specific surface area, which reduces the dust removal efficiency. However, the droplet size is too small, and it is easily vaporized or taken away by the airflow, which increases the load of the mist eliminator, and directly reduces the amount of droplets sprayed and washed, which will also affect the dust removal efficiency.

Five: equipment technical characteristics

1. Novel structure: change the contact mode of conventional gas-liquid two-phase cross-flow;

2. Large air volume: 36% larger than the sieve tray and valve tray;

3. Small pressure drop: 16% smaller than conventional absorption tower;

4. High purification efficiency: the purification efficiency can be as high as 95% or more.

SIX:Technical performance and technical parameters

| Model | LYT-500 | LYT-1000 | LYT-2000 | LYT-3000 | LYT-4000 | LYT-5000 |

Handling air volumem3/h | 5000 | 10000 | 20000 | 30000 | 40000 | 50000 |

Tower diametermm | 850 | 1200 | 1700 | 2100 | 2400 | 2700 |

Tower heightmm | 3800 | 4500 | 5200 | 5800 | 6500 | 7400 |

Air intake sizemm | 300×300 | 300×600 | 500×750 | 600×900 | 700×1000 | 800×1200 |

Exhaust port sizemm | Φ450 | Φ600 | Φ850 | Φ1000 | Φ1200 | Φ1300 |

Weight kg | 1000 | 1600 | 2200 | 2800 | 3400 | 4000 |