LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

THREE: Process principle

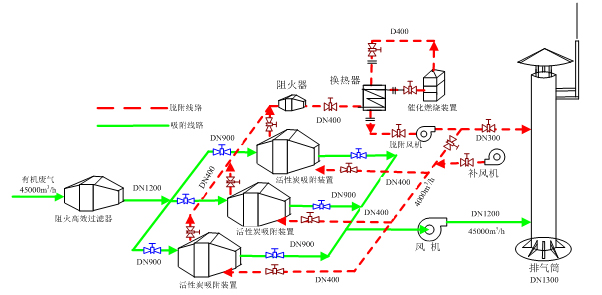

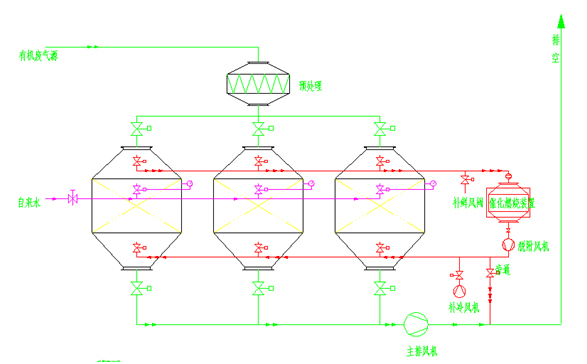

The device is designed according to the two basic principles of adsorption (high efficiency) and catalytic combustion (energy saving). First, the organic waste gas is adsorbed with activated carbon, and the adsorption is stopped when it is almost saturated, and then the organic matter is desorbed from the activated carbon by hot air flow to regenerate the activated carbon; the desorbed organic matter has been concentrated (the concentration is more than ten times higher than the original) and It is sent to the catalytic combustion chamber for catalytic combustion into carbon dioxide and water vapor. When the concentration of organic waste gas reaches more than 2000PPm, the organic waste gas can maintain spontaneous combustion in the catalytic bed without external heating. Part of the exhaust gas after combustion is discharged into the atmosphere, and most of it is sent to the adsorption bed for activated carbon regeneration. In this way, the heat energy required for combustion and adsorption can be met, and the purpose of energy saving can be achieved. After regeneration, the activated carbon can enter the next adsorption; during desorption, the purification operation can be carried out by another adsorption bed, which is suitable for both continuous operation and intermittent operation.

FOUR:Use

This purification device is mainly used for the purification and odor elimination of harmful organic waste gas volatilized or leaked from painting, printing, electromechanical, household appliances, shoemaking, plastics and various chemical workshops. The organic waste gas treated by direct combustion or catalytic combustion and adsorption recovery, especially for the treatment of large air volume, can obtain satisfactory economic and environmental benefits.

Five:performance and characteristics

1. The equipment has advanced design principles, unique materials, stable performance, simple structure, safety and reliability, energy saving and electricity saving, and no secondary pollution. The equipment occupies a small area and is light in weight. The adsorption bed adopts a drawer structure, which is convenient for filling and replacement.

2. Using a new type of activated carbon adsorption material - honeycomb block activated carbon, it is suitable for use under high air volume.

3. The catalytic combustion chamber adopts the precious metal catalyst with honeycomb ceramic shape as the carrier, which has low resistance and high activity.

4. The activated carbon bed for adsorbing organic waste gas is desorbed and regenerated with hot air after catalytic combustion, and the desorbed gas is sent to the catalytic combustion chamber for purification, without external energy, low operating cost, and significant energy saving effect.

SIX. Selection parameter table

Model | LXC-1000 | LXC-2000 | LXC-4000 | LXC-6000 | LXC-10000 | LXC-15000 | LXC-18000 |

Handling air volume(m3/h) | 10000 | 20000 | 40000 | 60000 | 100000 | 150000 | 180000 |

Organic waste gas concentration | ≤400mg/m3 | ||||||

Intake air temperature | ≤40℃ | ||||||

Purification efficiency | ~90% | ||||||

Installed power(Kw) | 60 | 72 | 81 | 120 | 150 | 180 | 210 |

Import size(mm) | 550×500 | 750×750 | 1200×950 | 1700×1000 | 2250×1250 | 2550×1650 | 3050×1650 |

Reference weight(Kg) | 3000 | 4500 | 10500 | 15000 | 22000 | 35000 | 45000 |

Note: 1. Special specification requirements, separate design