LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

ONE. Equipment overview

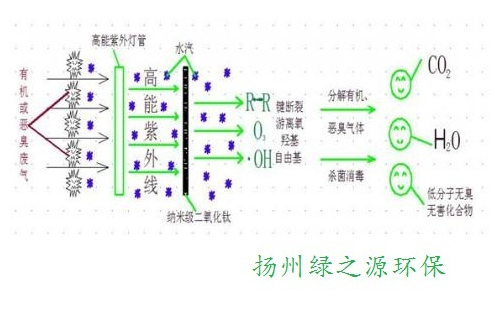

The photocatalytic purification device (LGO) generates photons of different energies through a special ultraviolet light source, and uses the strong absorption of photons by the odorous waste gas substances to dissociate and excite the odorous waste gas molecules under the bombardment of a large number of energy-carrying electrons, and make them free. The pollutant molecules in the state are combined with ozone oxidation to form small molecules of harmless or low-harm compounds, such as CO2, H2O, etc.

Deodorization and purification of odorous gases in refineries, rubber plants, chemical plants, pharmaceutical plants, sewage treatment plants, garbage transfer stations, etc.

2. Safe, reliable and adaptable: Due to the principle of photolysis, the module adopts explosion-proof treatment, which eliminates potential safety hazards, and has good fire-proof, explosion-proof and anti-corrosion performance (all stainless steel 304# structure), and the equipment performance is safe and stable. Through reasonable module configuration, it can be widely used in various types of organic waste gas and malodorous gas purification treatment. This equipment does not have any mechanical device, no movement noise, and can work continuously 24 hours a day. In addition to regular inspection and maintenance, there is no need for special personnel to manage and operate, the maintenance and energy consumption costs are low, and the purification treatment effect has obvious advantages.

Serial number | Device model | Air volume m3/h | Equipment size mm | Tuyere | Power w/ | wind resistance |

1 | LGO-100 | 1000 | 700×400×350 | 300×250 | 550w/220v | <50 |

2 | LGO-300 | 3000 | 850×500×500 | 400×400 | 1050w/220v | <50 |

3 | LGO-500 | 5000 | 870×750×950 | 650×750 | 1300w/220v | <50 |

4 | LGO-750 | 7500 | 870×750×950 | 650×750 | 2000w/220v | <50 |

5 | LGO-1000 | 10000 | 950×750×960 | 650×750 | 2600w/220v | <50 |

6 | LGO-1500 | 15000 | 1050×1000×1700 | 800×400 | 4500w/220v | <50 |

7 | LGO-2000 | 20000 | 1050×1000×1700 | 800×400 | 6000w/220v | <50 |

8 | LGO-3000 | 30000 | 1700×1500×2100 | 1500×700 | 7800w/220v | <50 |

9 | LGO-5000 | 50000 | 3200×2000×1800 | 1800×1400 | 13000w/220v | <50 |

扬州绿之源环保科技有限公司 0514-84756600