ONE:Overview: Catalytic Combustion Device (LCO) is a product developed by our company after years of research and based on the combination of theory and practice, and is widely used in domestic and foreign markets. Excellent performance, reliable quality is a powerful interpretation of the LCO itself. The product has significant environmental and social benefits and has been recognized by many users.

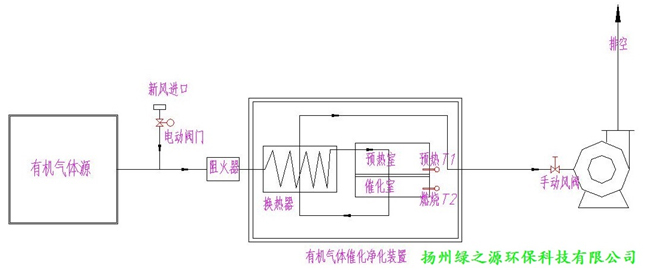

TWO. Process flow:

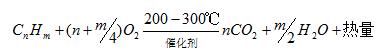

THREE. Process principle:Using the catalyst as an intermediate, the organic gas can be turned into harmless water and carbon dioxide gas at a lower temperature, namely:

The organic gas first passes through the dust removal and flame arrester system, then enters the heat exchanger, and then is sent to the heating chamber. The heating device makes the gas reach the combustion reaction temperature, and then through the action of the catalytic bed, the organic gas is decomposed into carbon dioxide and water, and then enters the The heat exchanger exchanges heat with the low-temperature gas, so that the temperature of the incoming gas reaches the reaction temperature, saving energy.

The basic principle of Catalytic Oxidation (LCO) technology is to use the energy required for the oxidation reaction of different organic substances to contact the catalyst surface with different characteristics to reduce the decomposition temperature of organic waste gas from 760 °C to about 250 °C, which reduces the operating cost of exhaust gas purification equipment.

FOUR. Equipment application range: 1. It can be used for the purification of organic solvents (mixed organic waste gas such as benzene, alcohol, ketone, aldehyde, ester, phenol, ether, alkane, etc.).

2. Suitable for organic waste gas purification in wire, cable, enameled wire, machinery, motor, chemical industry, instrument, automobile, bicycle, motorcycle, engine, tape, plastic, household appliances and other industries.

3. It can be used in drying lines such as various drying tunnels, printing iron cans, surface spraying, printing ink, motor insulation treatment, leather shoe viscose, etc., to purify the organic waste gas generated by each process.

4. The following substances cannot be contained in the exhaust gas: grease with high viscosity, phosphorus, bismuth, arsenic, antimony, mercury, lead, tin, high concentration dust.

Five. performance characteristics: 1. Easy to operate: When the equipment is working, it can realize automatic control.

2. Low energy consumption: When the equipment starts, it takes about 45 minutes to heat up to the light-off temperature. The energy consumption is only the fan power, and it will automatically compensate when the concentration is low.

3. Safe and reliable: The equipment is equipped with fire-resistant dust removal system, explosion-proof pressure relief system, over-temperature alarm system and advanced automatic control system.

4. Low resistance and high purification rate: The honeycomb ceramic carrier catalyst impregnated with today's advanced precious metals palladium and platinum has a large specific surface area.

5. The waste heat can be reused: the waste heat can be returned to the drying tunnel to reduce the power consumption in the original drying tunnel; it can also be used as a heat source in other aspects.

6. Small footprint: only 70%~80% of similar products in the same industry, and there are no special requirements for equipment foundation.

7. Service life of catalyst: 8000~13000 hours.

SIX. Selection parameter table

Product number | LCO -100 | LCO -300 | LCO -500 | LCO -800 | LCO -1200 | LCO -1500 | LCO -2000 |

The amount of waste gas treated m3/h | 1000 | 3000 | 5000 | 8000 | 12000 | 15000 | 20000 |

Type of waste gas treated | Benzenes, ketones, alcohols, aldehydes, esters, ethers, alkanes and other organic mixed gases |

Exhaust gas concentration range | 500~6000 mg/m3(Mixed exhaust gas 1/4) Lower explosion limit |

Purification efficiency | 95~97% |

Preheat power Kw | Electric (natural gas) heating power |

42 | 72 | 96 | 159 | 240 | 273 | 336 |

Running power Kw | 0~100%Gap compensation (adjusted according to exhaust gas concentration)

|

Fan power Kw | 3 | 7.5 | 11 | 15 | 18.5 | 22 | 37 |

outside

shape

ruler

Inch | Long mm | 1150 | 1560 | 1560 | 1800 | 1980 | 2450 | 3400 |

Width mm | 1050 | 1370 | 1540 | 2000 | 2240 | 2680 | 3120 |

High mm | 2100 | 2250 | 2300 | 2420 | 2510 | 2580 | 2620 |

注:1、特殊规格要求,另行设计

Lvzhiyuan

Lvzhiyuan