LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

ONE:Overview

There are many ways to purify organic waste gas, such as direct combustion and catalytic combustion, but it is difficult to completely burn waste gas with low concentration and large air volume, and the waste heat cannot be fully utilized in intermittent operation. The activated carbon adsorption method has its unique advantages. The LX type exhaust gas purification device applies the activated carbon adsorption principle, and improves the design of the adsorption characteristics of similar products. The device handles large air volume, adopts pneumatic valve, and the operation and management are simple and safe.

2.2. It is used for organic solvent factories and workshops that are ready to be recycled and reused in large air volume, low concentration exhaust gas conditions or intermittent operations.

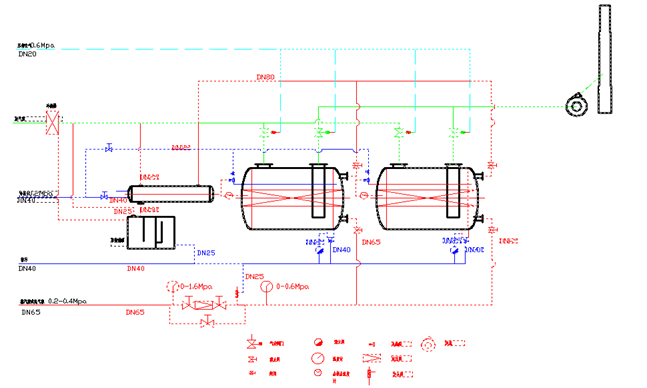

This purification device can set up single tank and double tank according to the production process. Generally, a single tank is set up for intermittent production; two adsorption tanks are set up for continuous production, one for adsorption and one for desorption, or two tanks can be used at the same time. The air inlet and outlet of the device are equipped with manual or pneumatic valves, which are easy and reliable to operate. Two tanks can be adsorbed at the same time and analyzed at the same time regularly, the air volume can be nearly doubled, and the investment and floor space can be reduced for intermittent production.

Five. user selection requirements

5.1 The exhaust gas inlet temperature of the device should be lower than 40℃. If the exhaust gas higher than 40℃, an air cooling device should be added, and it will enter the adsorption tank after cooling.

5.2 For the purification of exhaust gas containing more particulate dust produced by painting operations, the exhaust gas should be filtered and purified first.

5.3 When the adsorbed organic solvent has a high boiling point (above 120°C), a steam filter can be used to increase the desorption steam temperature.

SIX. LX series activated carbon adsorption device performance parameter table

Product number | LX-100 | LX-200 | LX-300 | LX-600 | LX-800 | LX-1000 | |

The amount of waste gas treated m3/h | 1000 | 2000 | 3000 | 6000 | 8000 | 10000 | |

Exhaust gas concentration mg/m3 | ≤1000 | ||||||

Inlet temperature ℃ | <40 | ||||||

Purification efficiency | ≥90% | ||||||

Type of waste gas treated | Triphenyl, ketone, alcohol, aldehyde, aldehyde, ester and other organic mixed gases | ||||||

Steam consumption | Each kilogram of solvent requires 3∽5 kilograms of steam, each time is calculated as 3 hours | ||||||

Fan power kw | 3 | 4 | 7.5 | 15 | 22 | 30 | |

Import and export size mm | φ200 | Φ300 | Φ350 | Φ400 | Φ500 | Φ600 | |

Steam port size mm | DN32 | DN40 | DN40 | DN50 | DN65 | DN80 | |

Install | Long mm | 2000 | 2500 | 2800 | 3200 | 3600 | 4500 |

Width mm | 1200 | 1400 | 1600 | 2400 | 2600 | 2600 | |

High mm | 2200 | 2600 | 2600 | 3300 | 3500 | 3250 | |

Activated carbon service life | 6000 hours | ||||||