LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

The water curtain spray booth (LSQ) is a technologically advanced paint mist purification treatment equipment, which can provide a better painting operation environment, improve the surface spraying quality of the workpiece, and improve work efficiency; Treated with paint mist, or used alone, it has a good effect on improving the workshop operating environment and purifying paint mist.

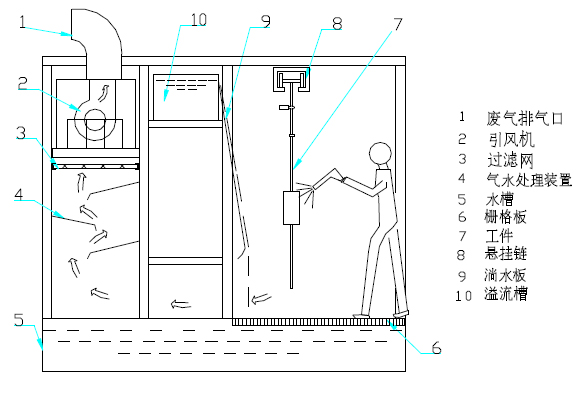

When spraying paint, the paint mist and overspray paint mist inside the chamber will form a certain negative pressure wind speed (wind speed between 0.4~0.5m/s) at the operation port under the forced action of the induced draft fan, from top to bottom. , The workpiece is placed in a uniform flow layer with a certain wind speed, so that the splashing waste paint mist is pressed into the water tank, which not only improves the working environment, but also ensures the quality of the coating. The paint mist is treated by placing the water curtain on the side of the chamber body, and after separation of gas and water, under the adsorption of activated carbon, the clean air is sent to the atmosphere through the exhaust system. The water containing paint mist flows into the circulating pool, and is purified by coagulation (regularly adding special paint mist coagulant to the water) and then sent to the spray booth by the circulating pump for recycling. The floating paint residue is regularly removed and then buried or incinerated.

THREE:Equipment composition:

The main structure and components of the equipment: when painting, it has the functions of ventilation, lighting, single-station painting, paint mist treatment, waste gas treatment and labor protection. The equipment is mainly composed of chamber body, artificial door, inspection door, lighting, water tank, paint mist filter, blower, ceiling filter cotton, water pump and regulating valve, circulation pipeline, water curtain plate water film, nozzle nozzle and paint mist treatment system , exhaust fan, exhaust gas purification, exhaust duct, electronic control system and other components.

Equipment material: carbon steel + anti-corrosion paint; or galvanized steel sheet, stainless steel; galvanized pipe, stainless steel mesh, etc.

FOUR:The main performance parameters can be customized according to the requirements of spraying products

1. The main dimensions of the chamber body: L*H*W= length (1.2~5.0m)*W width (2.5~4.0m)*height (2.2~3.5m);

2. Illumination: 500~800 Lux;

3. Operating surface wind speed: V=0.35~0.55m/s;

4. Air supply or air inlet filter and purify, normal temperature;

5. Air exhaust volume: 8000m3/h~40000m3/h;

6. Paint mist purification efficiency: ~95%.

FIVE:Main Specifications

Dimensions | Illuminance(Lux) | Cross-sectional wind speed(m/S) | Exhaust volume(m3/h) | Circulating water volume(m3/H) | Equipment noise dB(A) | Paint mist purification efficiency(%) | Installed power(kw) |

1800*1500*2000 | 600 | 0.45 | 8000 | 12 | <80 | 95% | 5.5 |

2000*1800*2200 | 600 | 0.45 | 10000 | 15 | <80 | 95% | 7.5 |

2500*2200*2400 | 600 | 0.45 | 15000 | 23 | <83 | 95% | 11 |

3000*2600*2600 | 600 | 0.45 | 18000 | 30 | <83 | 95% | 15 |

3600*2800*2800 | 600 | 0.45 | 21000 | 33 | <85 | 95% | 18.5 |