LINK:

Lvzhiyuan

Lvzhiyuan

Lvzhiyuan

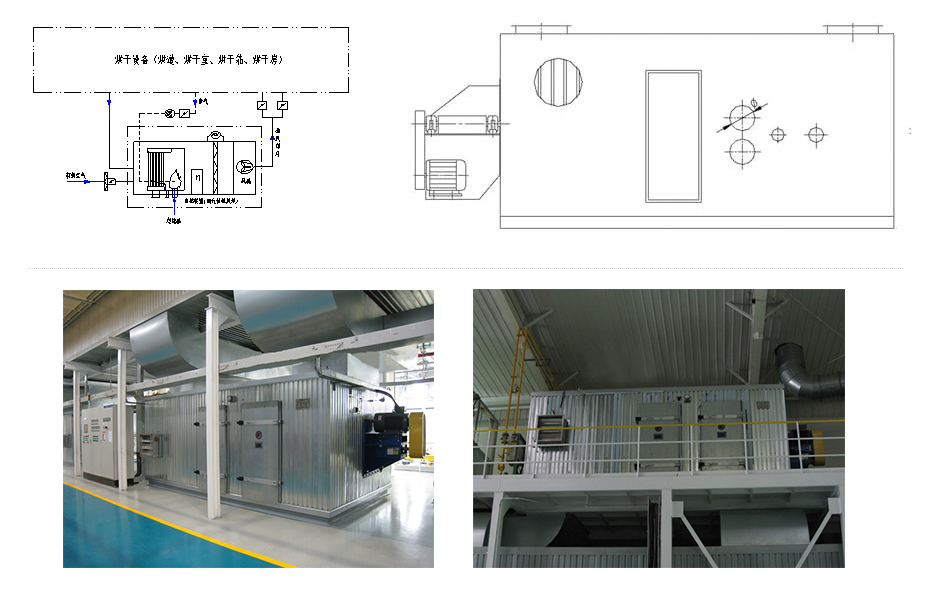

The circulating hot air heating device used in the drying room, drying room, and drying tunnel on the spraying production line of automobile products, surface spraying of construction machinery, household appliances, various electronic products, etc., adopts heat source (natural gas, liquefied gas, diesel oil, or Steam, heat transfer oil, electricity, etc.) heating; the (indirect) heating heat exchanger, high temperature filter, circulating fan, and three functional units are assembled on the insulation box to form an integrated circulating air heating device (equipment ), referred to as "ternary body" hot blast furnace (LRF) in industrial design, referred to as "ternary body" hot blast furnace or "ternary body" heating device.

If the organic waste gas that volatilizes and overflows during the drying process is introduced into the high-temperature furnace with the function of waste gas incineration structure for purification, this type of hot blast stove is also called "quaternary" hot blast stove or heating device.

The "ternary body" hot air heating furnace has a modular structure, and has the advantages of energy saving, high efficiency, safety, and high circulating hot air quality. , In recent years, it has been widely used in many spraying production lines and drying equipment, and the effect is remarkable, and it is very popular among engineers and technicians and users.

9. The "quaternary" hot blast stove purifies the organic gas emission to meet the comprehensive emission standard of air pollution (GB16297-1996).

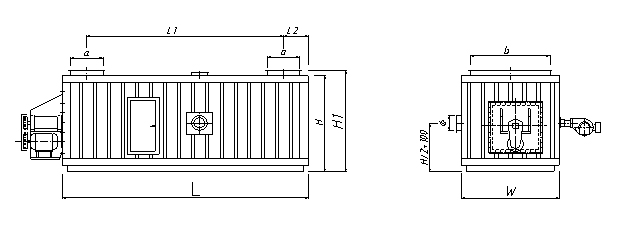

FOUR:Specifications, models and installation dimensions of "ternary body" hot air heating furnace:

Serial number | Product number | Calories (10,000 Kcal/h) | Air volume m3/h | Length(L)㎜ | Width(W)㎜ | High(H)mm | L1 | L2 | h1 | a*b/mm | φa/mm |

1 | LRF-Q-15 | 15 | 13000 | 4000 | 2300 | 2240 | 400 | 3200 | 2340 | 500*2000 | 200 |

2 | LRF-Q-20 | 20 | 18000 | 4000 | 2300 | 2240 | 400 | 3200 | 2340 | 500*2000 | 200 |

3 | LRF-Q-25 | 25 | 23000 | 4000 | 2300 | 2240 | 400 | 3200 | 2340 | 500*2000 | 200 |

4 | LRF-Q-30 | 30 | 27000 | 4600 | 2600 | 2240 | 455 | 3690 | 2340 | 610*2300 | 300 |

5 | LRF-Q-35 | 35 | 32000 | 4600 | 2600 | 2240 | 455 | 3690 | 2340 | 610*2300 | 300 |

6 | LRF-Q-40 | 40 | 38000 | 4600 | 2600 | 2240 | 455 | 3690 | 2340 | 610*2300 | 300 |

7 | LRF-Q-45 | 45 | 42000 | 4600 | 2600 | 2240 | 455 | 3690 | 2340 | 610*2300 | 300 |

8 | LRF-Q-50 | 50 | 47000 | 4600 | 2600 | 2240 | 455 | 3690 | 2340 | 610*2300 | 360 |

9 | LRF-Q-55 | 55 | 51500 | 4600 | 2600 | 2240 | 500 | 3690 | 2340 | 700*2300 | 360 |

10 | LRF-Q-60 | 60 | 57000 | 4900 | 3000 | 2240 | 500 | 3900 | 2340 | 700*2700 | 360 |

11 | LRF-Q-70 | 70 | 59000 | 4900 | 3000 | 2240 | 500 | 3900 | 2340 | 700*2700 | 360 |

12 | LRF-Q-80 | 80 | 65000 | 6600 | 3400 | 2540 | 500 | 4650 | 2640 | 7003100 | 400 |

13 | LRF-Q-90 | 90 | 81000 | 6600 | 3400 | 2540 | 550 | 4700 | 2640 | 800*3100 | 400 |

14 | LRF-Q-100 | 100 | 89000 | 6600 | 3400 | 2540 | 600 | 4700 | 2640 | 900*3100 | 450 |

15 | LRF-Q-110 | 110 | 98000 | 6600 | 3400 | 2540 | 650 | 4900 | 2640 | 1000*3100 | 500 |

16 | LRF-Q-120 | 120 | 108000 | 6600 | 3400 | 2540 | 700 | 5050 | 2640 | 1100*3100 | 500 |